With significant growth across industrial verticals, increased worldwide market penetration, and ongoing advancements in semiconductor technology, Kaynes Technology, a prominent electronics and embedded systems firm, maintains its remarkable progress in 2025. design and electronics manufacturing services (EMS). With its headquarters in Mysuru, India, the company has evolved into a major player in offering solutions from concept to commissioning.

The current year has become pivotal for Kaynes Technology, marking a rise in demand for high-quality embedded systems, smart manufacturing capabilities, and IoT-driven solutions across industries. By leveraging cutting-edge automation and R&D capabilities, Kaynes is not just riding the digital transformation wave but actively shaping it. The company’s robust partnerships with global OEMs and its commitment to sustainability have further elevated its status. In 2025, the business is increasingly targeting sectors such as electric vehicles, aerospace, defense, and medical technology.

Current Services Offered by Kaynes Technology in 2025

The company’s wide range of offerings in 2025 covers multiple industries like automotive, aerospace, industrial, medical, and railway electronics. With tailored EMS and embedded design capabilities, Kaynes delivers specialized solutions across each domain. Its scalable infrastructure supports both low and high-volume production needs. Strategic partnerships and domain-specific R&D keep its offerings industry-relevant. Below is a structured snapshot of their major services:

| Service Segment | Description | Primary Industries Served |

| Embedded Design Services | PCB Design, Firmware Development, Embedded Software | Automotive, Healthcare, IoT |

| Electronics Manufacturing Services (EMS) | End-to-End Assembly, SMT, Through-Hole, Box-Build | Consumer Electronics, Defence, Railways |

| ODM (Original Design Manufacturing) | Product Lifecycle Support and Custom Electronics | Industrial Automation, Robotics |

| IoT and Smart Solutions | Connected Devices, Cloud Integration, Analytics | Smart Cities, Smart Healthcare |

| Testing and Validation | Environmental & Functional Testing | Aerospace, Medical Instruments |

Expansion Strategies and Global Outreach

Kaynes Technology has made significant strides in foreign markets in 2025, particularly in Southeast Asia, Europe, and North America. Through its strategic acquisitions and global alliances, it has managed to penetrate demanding markets for industrial automation, smart mobility, and green energy. Export revenues are steadily rising, contributing significantly to its overall turnover.

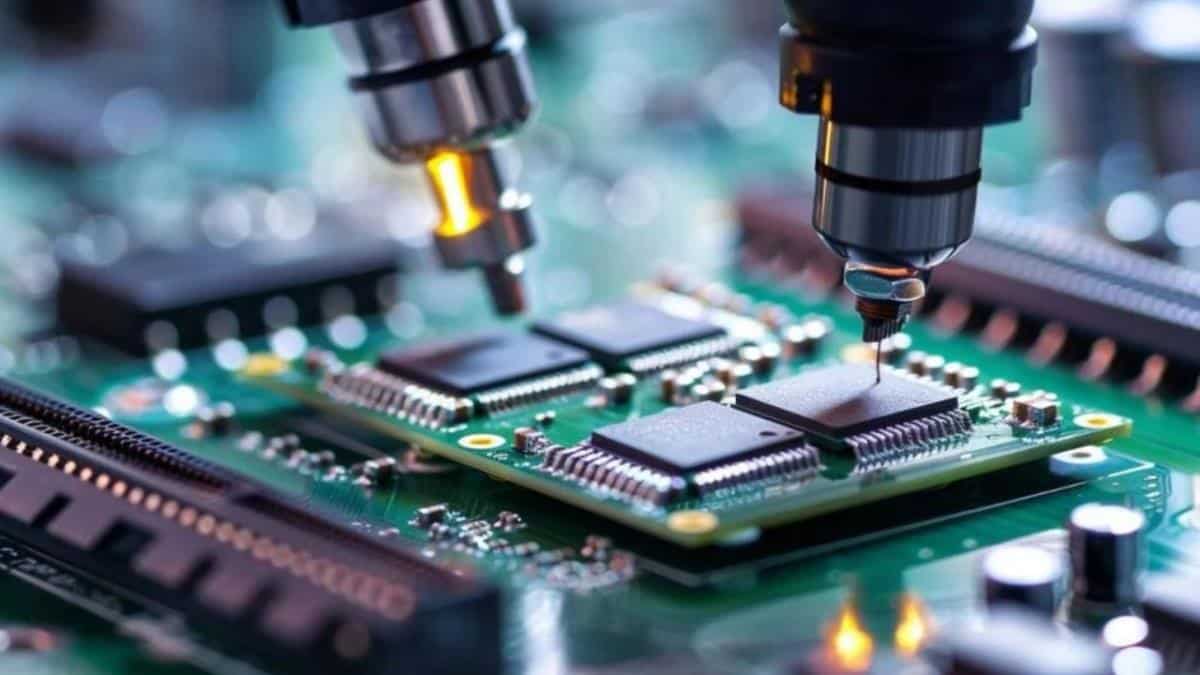

The company’s investment in cutting-edge R&D centers and smart factories aligned with Industry 4.0 standards has enhanced its competitiveness. A heavy focus on automation and robotics has allowed it to serve complex EMS requirements with speed and precision. Kaynes’ Mysuru and Bengaluru facilities are examples of efficient innovation hubs delivering scalable and modular production capabilities.

Financial and Market Performance of Kaynes Technology in 2025

Kaynes Technology’s financial indicators for 2025 signal strong growth momentum. The company has reported consistent year-on-year revenue increases, primarily fueled by demand for semiconductor-based products, smart embedded systems, and government-led initiatives like ‘Make in India’ and ‘Digital India.’ Its EBITDA margins have also improved, reflecting operational efficiency and high-value contract execution. Robust export volumes and strong domestic orders have further solidified its market position.

| Metric | FY 2024 (₹ Cr) | FY 2025 (Projected ₹ Cr) | Growth % |

| Total Revenue | 1,200 | 1,600 | 33% |

| Net Profit | 145 | 205 | 41% |

| EBITDA Margin | 17% | 19% | +2% |

| R&D Investment | 95 | 125 | 32% |

| Export Share | 22% | 30% | +8% |

Sustainability Initiatives and Green Manufacturing

Environmental consciousness is a cornerstone of Kaynes Technology’s manufacturing philosophy. In 2025, the company continues to prioritize sustainable manufacturing practices. Renewable energy usage in production facilities has increased by 40%, and waste recycling systems have been made more robust. With a shift toward RoHS (Restriction of Hazardous Substances) compliant components and processes, the company ensures its offerings align with global sustainability standards.

Green tech verticals like EV electronics, solar tracking devices, and battery management systems are also seeing a boost. Kaynes has partnered with government agencies for solar power hardware and smart grid electronics, contributing to India’s decarbonization roadmap.

Strategic Partnerships and Collaborations

Collaborative growth is one of the reasons behind Kaynes Technology’s rapid scale in 2025. To jointly develop solutions for automotive electronics, consumer-grade wearables, and smart factories, the company has forged important partnerships with companies like Siemens, Bosch, Qualcomm, and Tata Elxsi.

Academia-industry collaboration is also gaining momentum, with partnerships forged with IITs and global universities to foster innovation, sponsor research, and recruit fresh talent. These tie-ups are accelerating the development of AI-powered devices, edge computing modules, and high-frequency PCBs.

Digital Transformation and Smart Factory Ecosystem

Kaynes’ transition into a digital-first EMS provider continues with aggressive implementation of AI, IoT, and predictive analytics in its manufacturing operations. Smart monitoring systems, automated material handling, and energy-efficient workflows are helping the company reduce costs while improving quality. Its proprietary manufacturing execution system (MES) integrates real-time data analytics, allowing supervisors and clients to track assembly line performance remotely. This level of transparency and agility is increasingly appreciated by clients who demand speed and accuracy in product turnaround.

In 2025, Kaynes has also introduced AI-powered fault detection systems that minimize production errors and reduce rework rates. Machine-to-machine communication and digital twin models are further enhancing process simulation and preventive maintenance. These initiatives align with Kaynes’ commitment to Industry 4.0 and reinforce its competitive edge. The shift toward intelligent, data-driven manufacturing is enabling higher customization, shorter lead times, and superior operational efficiency.

Challenges and Risk Management in 2025

Despite strong performance, Kaynes Technology faces industry-wide challenges such as global chip shortages, rising component prices, and cyber threats. The company has mitigated some of these risks by building buffer inventories, investing in cybersecurity infrastructure, and increasing local sourcing to reduce import dependency.

It also faces workforce-related challenges, especially in sourcing specialized engineers. However, this has been partly addressed by internal training programs and collaborations with technical institutes to upskill young professionals in advanced electronics and automation.

Talent Development and Human Resource Focus

Workforce development is central to Kaynes’ 2025 roadmap. The company has introduced new training programs focused on embedded programming, PCB assembly automation, IoT product development, and quality assurance. Employee retention rates have improved through a mix of wellness initiatives, flexible work models, and performance incentives.

A new internship-to-hire program launched across Mysuru, Chennai, and Noida is tapping into fresh talent from engineering colleges and providing practical exposure in high-end manufacturing environments. Women’s participation in STEM roles has also increased, with targeted outreach and mentorship.

R&D Breakthroughs and Patented Technologies

In 2025, Kaynes filed multiple patents related to embedded sensor fusion, edge AI acceleration boards, and high-efficiency power modules. Its R&D team has delivered unique products for aerospace and defense clients that are now under evaluation for global deployment.

Innovation labs located in Mysuru and Hyderabad are working on technologies such as flexible circuit boards, quantum-safe cryptographic chips, and low-latency communication modules. These developments promise to shape the future of connected ecosystems and digital infrastructure.

Client Success Stories and Use Cases

Kaynes Technology has enabled several clients to meet time-critical and high-precision electronics needs. A notable case in 2025 is their collaboration with an EV manufacturer, where Kaynes co-designed and supplied integrated battery management modules, cutting production cost by 25%. Another success is with a U.S.-based healthcare device firm, where Kaynes provided end-to-end embedded design and testing services for a portable diagnostic unit. This solution not only passed FDA certifications but also achieved a 35% faster time-to-market.

In the aerospace sector, Kaynes partnered with a European avionics company to deliver flight-critical control systems under stringent safety standards. Additionally, they supported an Indian smart city initiative by deploying IoT-enabled energy management units across municipal infrastructure. Their flexible EMS model helped a consumer electronics brand in Southeast Asia recover from supply chain delays during global shortages.

The Road Ahead: Vision for 2026 and Beyond

Looking ahead, Kaynes Technology is set to expand further into AIoT (Artificial Intelligence of Things), wearable healthcare devices, and space-grade electronic systems. Plans are underway to establish a semiconductor fabrication R&D facility and to business possibilities in Latin America.

The leadership team has set clear goals to reach ₹2,000 Cr in revenue by FY 2026, expand export contribution to 35%, and double their R&D workforce. These plans will be supported by a mix of organic growth, joint ventures, and technological diversification.

Wrapping Up

As 2025 progresses, Kaynes Technology remains at the forefront of India’s advanced manufacturing and embedded system innovation. The company’s ability to adapt quickly to evolving technologies while maintaining high production standards positions it as a vital contributor to the global electronics supply chain. Strategic investments in AI, smart automation, and green manufacturing are laying the foundation for its long-term growth. Kaynes’ diversified portfolio and sectoral presence provide a buffer against market volatility, ensuring a stable financial trajectory.

Investors and analysts are optimistic, citing the company’s growing export footprint, streamlined operations, and vertically integrated capabilities. Its deep focus on talent development and technical excellence continues to be a cornerstone of its sustained success. With new product pipelines, expanded global alliances, and digital-first delivery models, Kaynes is poised for another year of scalable impact.

FAQs

What are the major services offered by Kaynes Technology in 2025?

In 2025, Kaynes Technology delivers a wide range of services, including embedded systems design, IoT solutions, original design manufacturing (ODM), and complete electronics manufacturing services (EMS). These cater to industries like automotive, healthcare, aerospace, and industrial automation. The company also provides testing, validation, and prototyping to ensure product reliability. Their vertically integrated model ensures speed, accuracy, and end-to-end accountability.

How has Kaynes Technology performed in terms of revenue growth in 2025?

Kaynes Technology has experienced strong financial performance in 2025, reporting a 33% rise in year-on-year revenue. This was largely driven by rising global demand for embedded solutions, along with increased export volumes. The company’s EBITDA margins also improved due to operational efficiency and automated production lines. Higher foreign investments and new government contracts boosted both profit and market share.

What are Kaynes innovation areas in 2025?

Kaynes continues to prioritize R&D with focus areas including AI integration, sensor fusion, and high-speed PCB design. Their teams have introduced next-gen embedded boards, EV control units, and real-time IoT devices. Innovations also include energy-efficient electronic modules for medical and industrial use. The growing patent portfolio in 2025 reflects their dedication to proprietary and future-forward technology.

What sustainability practices has Kaynes adopted in its manufacturing units?

Sustainability is a pillar of Kaynes’ operations in 2025. The company uses solar panels at major facilities and adheres to RoHS compliance for eco-friendly production. Their smart water recycling systems enable zero-liquid-discharge operations, cutting environmental waste. Additionally, energy-efficient lighting and HVAC systems help reduce carbon footprints across manufacturing zones.

What challenges does Kaynes face, and how is it handling them?

Kaynes Technology faces challenges such as semiconductor supply chain volatility, cybersecurity threats, and a shortage of skilled labor. The company has responded with proactive sourcing strategies, enhanced digital security protocols, and in-house talent incubation programs. Collaboration with universities and AI-based hiring tools is helping Kaynes secure and train next-generation engineers.

Which areas of the world will Kaynes be entering in 2025?

Kaynes has made significant strides in North America, Europe, and Southeast Asia in 2025. New manufacturing partnerships and export contracts have opened up opportunities in Germany, the U.S., and Singapore. Their focus is on high-potential sectors like electric mobility, medical electronics, and aerospace systems. These expansions are supported by localized teams and region-specific compliance standards.

How does Kaynes support startups and product innovators?

Kaynes offers incubation-like EMS and design support for startups, especially in medical tech, wearables, and automotive IoT. Their design-to-delivery model allows innovators to prototype quickly, scale efficiently, and enter the market faster. Access to their advanced labs, experienced engineers, and global supply network helps reduce time-to-market and technical risks. Many startup clients report cost savings and faster product iterations through Kaynes’ support.